The manufacturing processes of skate frames

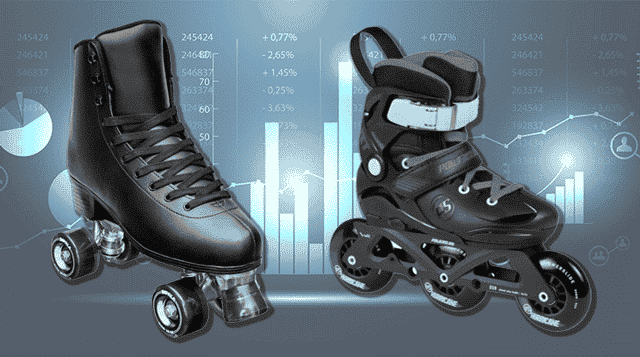

The frame is a key-part of our skates. Its shape, its length and its rigidity vary according to the discipline and the needs of the skater. Made of composite or polyurethane, they are molded or injected, just like boots. Made of aluminum, they may be pressed, extruded or machined from billet. What are the differences between theses manufacturing processes?

Par Vernon SULLIVAN

Designing frames

Composite frames

Let’s not dwell on the manufacturing of frames made of plastic material and composite, as a very complete article is available on the link below.

Let’s not dwell on the manufacturing of frames made of plastic material and composite, as a very complete article is available on the link below.

Read article on the making of composite frames (soon).

Metal frames

Naturally, just like molded frames, metal frames are also developed and designed by C.A.D.

Some advanced softwares even enable to make force tests during their conception. The designer and the engineer can define together whether the thickness of a side should be increased or reduced, if they should add a deck, take off material in some part…

The frames may be extruded, pressed or machined according to the use, the price you are ready to pay and the quality you want.

The first difficulty in the designing of a frame is to manage to optimize the weight, the resistance, the rigidity and the height especially since the arrival of bigger-diameter wheels of 90, 100 even 110 mm and more.

Pressing, an inexpensive method

The pressing is a simple manufacturing technique which consists in pressing an aluminum foil (or other metal) of the thickness that you want. The material is deformed to get the wanted shape.

Most of the time, the two sides of a frame are made separately. They are put together later, thanks to a central part onto which they are fixed.

That process is used on most of high-end frames. Indeed, it is less expensive than extrusion. The manufacturer wastes less material and the frame does not have to be threaded to insert simple axles, contrary to extruded models. Thus, costs are reduced.

Pressed frames offer a better performance than nylon and glass fiber composite frames for example, but are limited compared to extruded models, which are far more rigid.

The manufacturing of an extruded frame

The process of extrusion is simple: a block of aluminum is put under pressure and forced to go through a canal. The obtained shape will be reworked until it gets the shape wanted by the manufacturer. That technique conveys a good rigidity to the frame.

Then, it is often anodized to improve its resistance to corrosion.

The frame may be decorated in changing colors of the anodization baths. The norms used are often the same as those in aeronautics (Aluminum 6000, 7000…)

Tops: frames machined from billet

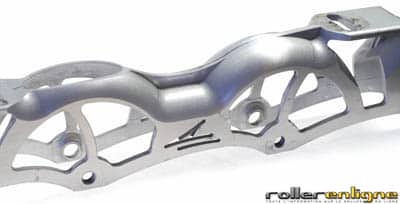

In a way, a frame machined from billet is ‘sculpted’ from a block of aluminum. Here we are talking about small series of production, and at the very high-end range.

The material used is so rigid that a press with a considerable strength is needed to bend it. That manufacturing process enables to make things that would be impossible with a classic shape. Only a few manufacturers use that almost hand-crafted process. In France, the Diabolik frames are made thanks to that process.

The finishing of aluminum frames is extremely detailed. Everything is made by numerically controlled machine. The frame cuttings are perfected with laser. Around 10 operations are needed to complete an aluminum frame. Then the brands often append a printing on the frames: either by anodization, just as seen earlier, or by adding a simple layer of paint.

|

|

Useful links

Extracting an axle or a screw stuck in a frame

The maintenance of your skate frame

Well choosing your speed skating frames

Powerslide is working on a new UFS off-road frame

Cadomotus DualBox® 5 frame: Inside the Design

Translation: Chloé Seyres

Pictures: Alfathor, Diabolik, all rights reserved