Cadomotus DualBox® 5 frame: Inside the Design

Cadomotus DualBox® 5 frame: Inside the Design

Par alfathor

Active Intelligence, it’s the principle that drives CadoMotus engineers forever forward in pursuit of breakthrough innovation design that enhances the efficiency and power of an inline speedskater’s athletic performance. Untiring dedication to design refinement and utility improvement have established the DualBox® design architecture as a leading platform for inline speed skating frames. When you’ve already established a baseline this high, gain is only achieved through a measured process of prototyping, experimentation, proofing and manufacturing. It’s this attention to the smallest technical details that sets CadoMotus engineering apart from the field, and keeps our skaters out front and on the podium.

With this in mind, when the complex and demanding project of designing the next generation of DualBox® frames was given the green-light, our overriding goal was to ensure that a lighter frame would not compromise the unique characteristics of the DualBox® design:

- more stability – even force distribution

- less muscle fatigue – vibration mitigation

- more control – predictable responsiveness

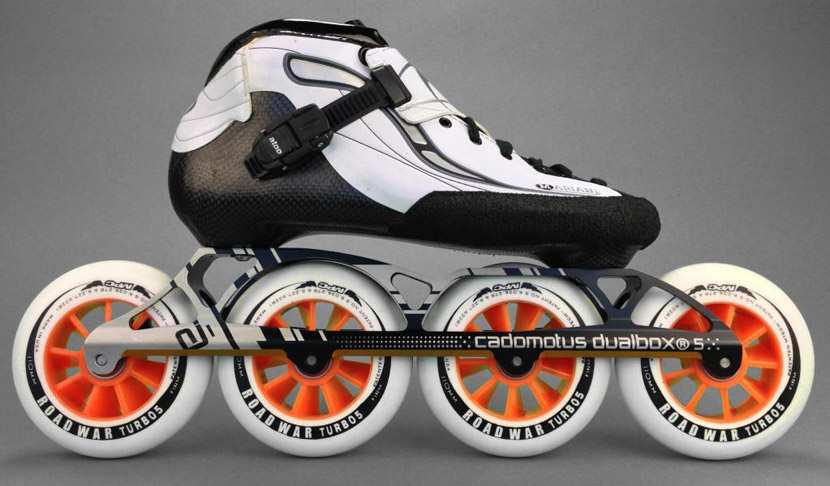

Maintaining these design advantages was the first task. They’re the result of the patented DualBox® tubular side walls that run the length of the frame from front-to-back, without intersections or joints. DualBox’s uniquely different design affords skaters an advantage over other frames that have typical bridge reinforcements in between the wheels. It’s this distinctive that provides the DualBox design even force distribution and tighter control. Other frames are inconsistent when it comes to stiffness and flexibility, disrupting power flow and transfer, hurting control. DualBox® technology ensures that CadoMotus frames offer the control skaters need to accelerate and maintain top speeds in the most efficient manner possible. It’s this efficiency that drives long-term success on the road and track.

To preserve these attributes and achieve the goal of making the frames lighter, CadoMotus engineers combined the DualBox® concept of the tubular side walls with CNC machining from a solid block of aluminum. It’s through this method we achieve geometric freedom to create bridges and cutouts in the most advantageous directions possible, as opposed to machining from an extruded piece of aluminum that dictates design by its very nature. It was through combining both concepts that our engineers could make the DualBox 5 frame 30g lighter than the DualBox-IV.

Aesthetically, the tubular side walls are lower but wider than the DualBox IV. Structurally, the beefier width increases the torsional and bending stiffness, and because we’ve reduced the overall height, the frame is lighter. Stylistically, the new design exposes more wheel, thus you can visually see the frame even looks lighter.

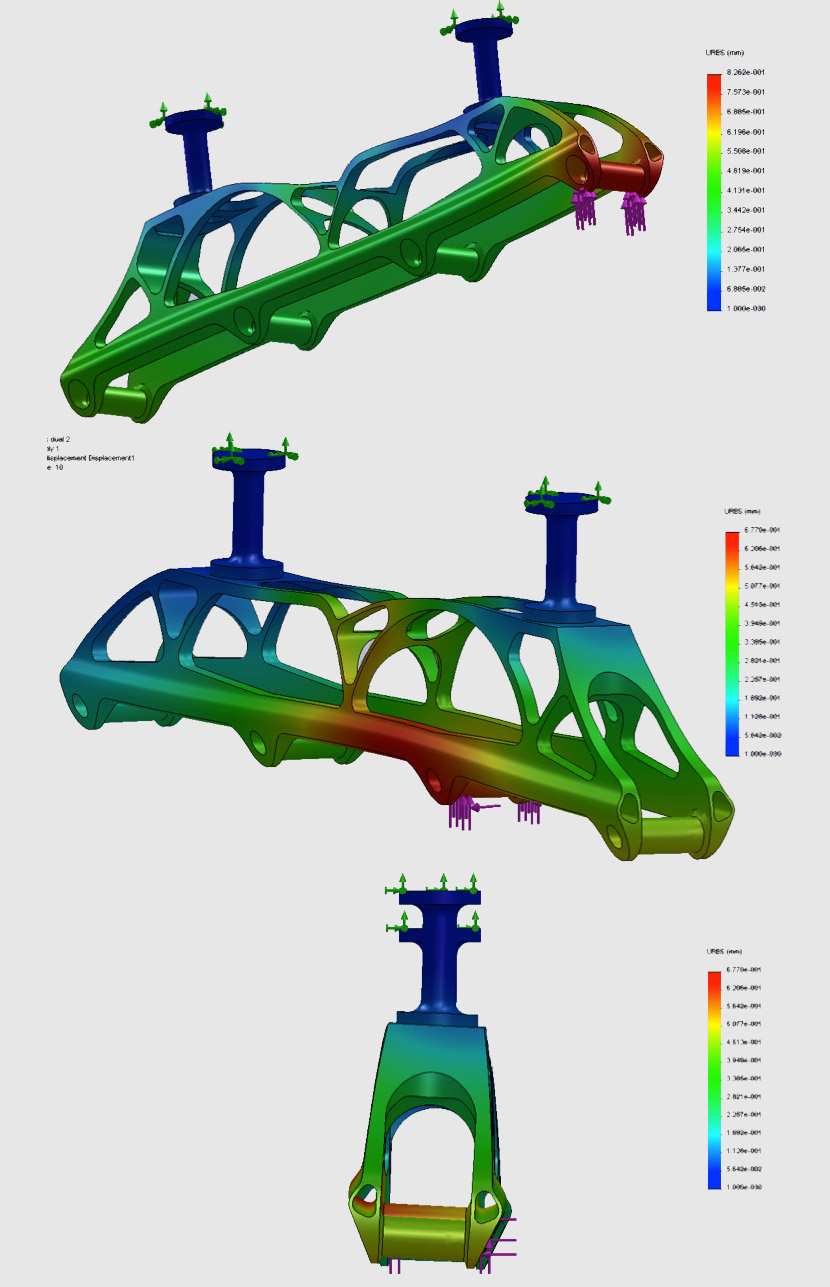

In order to preserve the structural integrity of the DualBox® design, our team paid extra attention to the ultra-thin parts that could possibly crack and brake under pressure. Our design engineers have done enhanced FE calculations to mitigate and all but eliminate any possible vulnerabilities in our stringent drive to eliminate any possible structural defects. It was through proofing at this advanced level that our designers learned where we had to reshape the frame in some critical areas, such as the rear deck, close to the mount slot, because through testing we saw that this was where many frames break. And through this type of testing and design refinement we discovered that, like any good design process, there’s give-and-take at play. We were able to bring innovation to this next generation DualBox design and produce an overall leaner frame by balancing out in other areas, such as in the center, because it was observed that as the design evolved, we were over-compensating with material that were adding unnecessary weight. And as a result, we made steering easier in the process, enhancing performance in an intelligent way, without compromise. That’s the heart of the CadoMotus innovation process.

When testing power transfer and force application, we created simulations in four critical on-skate situations when the most energy is exerted on the frame. In these four critical situations, the frame’s displacement and material stress measures are exposed. In the heat map you can see the different colors on the pictures that expose the level of stress in the material.

It’s through these metrics that our engineers are able to discern how the frame will skate. For skaters, it’s knowing that steering responsiveness and predictability is dependent upon simply maintaining pressure at critical points. For the manufacturer, it’s the knowledge of what modification in geometry can be tweaked in the design in order to improve its performance.

And last but not least, it’s the FE analyses that our engineers have do in repeated lab-testing on prototype frames that validates all of the calculus, providing a check and balance to the computer generated specifications. It’s in this way that we achieve Active Intelligence, so that we know that what’s in our hands will perform exactly as we want, and our skaters need.

The science of Intelligent Motion is no mistake, it can’t simply be copied. It’s a meticulous process that never appeases or compromises in pursuit of design excellence. In the DualBox® V, you’ve got the best minds in the sport under your feet, powering your stride, giving you the competitive edge that is the Speed of Intelligent Motion.

Read complete article on the blog of cadomotus