Extracting an axle or a screw stuck in a frame

Most of beginners are afraid to lose a screw or an axle while skating. They often tighten their roller-skates axles too much. When the axles are stuck in the frame, it becomes very hard to remove them. It also happens that the allen key erodes the thread. Here are some tips to remove stubborn axles and screws...

Par alfathor

Different methods in different situations

Race single axle or axle with a screw?

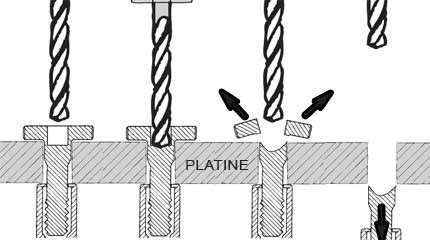

First thing: identify the nature of your axles! The entry-level models are often equipped with a screw axles, whereas on most high-end skates single axles are more common. A single axles consists of one piece (A statement of the obvious). The head of the axle is threaded.

First thing: identify the nature of your axles! The entry-level models are often equipped with a screw axles, whereas on most high-end skates single axles are more common. A single axles consists of one piece (A statement of the obvious). The head of the axle is threaded.

Try the gentle method: lubricants

Before leaving the heavy artillery, you can already try to use a penetrating oil to remove the axle: The WD40 works well… or a 3 in 1 lubricant.

If this is not enough, try a Torx (star head) …

- Insert a Torx key in the axle. A worn axle has a larger imprint, so the key has to be larger too (see the image below)…

- Give a good hammer to insert the tool in the axle and get enough grip

- You can add some oil on the thread on the opposite side

- Screw a little bit before unscrewing

- If this does not work, try another method

Note: The Torx key to be used is T25 if the axle is still in good condition or T27 if the axle is really worn.

The manipulations that follow should be performed with great caution. The drill can slip and hurt you … We advise children to let their parents do it!

Axle with screw?

When the allen imprint is worn and eroded after many assembly and disassembly, you have 2 solutions:

- Either you make a notch with the hacksaw on the screw head if it is possible to do it without damaging the frame.

- Either you drill!

Making a notch to use a slot screwdriver

As explained in the previous paragraph, this solution does work if the head of the screw is large enough to be dug with a hacksaw without damaging the frame.

- Secure the frame to prevent it moving

- Use a hacksaw to cut a flat slot in the screw head

- Be careful not to attack the material of the frame!

- If the notch is deep enough, a screwdriver can have enough grip

- Unscrew… job’s done!

The drilling of the screw

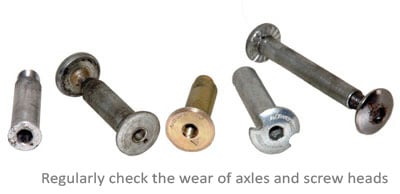

The purpose of the drilling will be to separate the screw head from the rest of the screw

- find a metal drill – approximately the same width as the imprint of the allen key (4-5 mm).

- Block the frame as much as possible to prevent it from moving during drilling, if you have a vice, it’s the best!

- Put the drill at low speed and get the drill in the axis of the screw head

- The drill will « eat » the material of the screw width and depth

- If the drill is large enough, the screw head will jump, the screw will be cut in half

- Thus, you only have to separate the head from the rest of the screw

- Then pull the axle down if you have enough grip, or else push it down with a screwdriver or another tool …

Is there any way to recover the axle?

Life of the screw stops there, but you may be able to recover the axle!

- Hold the axle in a vice

- Tighten the screw stuck in the axle with pliers

- Try to unscrew … if it works, you saved the axle!

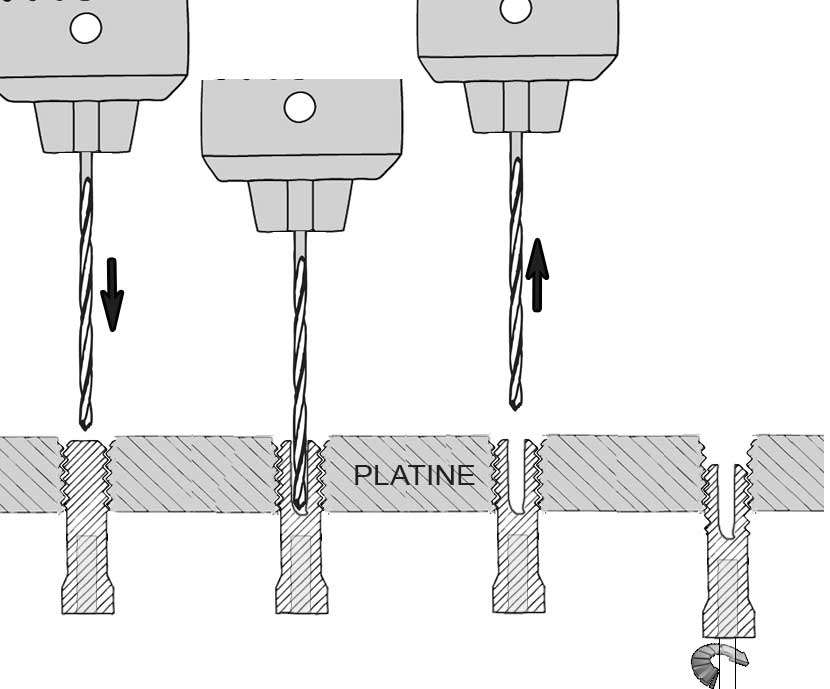

Removing a race single axle

The axes used on speed-skaces are single axles. The imprints are often worn by allen keys. These axles are made?in one piece so there is no possibility of breaking the head … and it would be useless since the thread is at the bottom of the axle.

In addition, single axles are totally integrated into the frame, there are few options to extract them.

- Either you are able to insert a small screwdriver deep enough into the axle to unscrew it…

- Either you can try a ratchet tap wrench (the best solution)

- Either you have to drill! (the worst solution)

A « ratchet tap wrench », How does it work?

There is a tool that removes the axles without drilling: a « ratchet tap wrench ». Its thread is reversed, so you screw to unscrew. It can be usedul in many situations…

- Insert the « ratchet tap wrench » in the imprint of the axle (allen or Torx imprint, depending on the brand of your axles)

- Screw the tool gradually (in this case, unscrew to screw over the usual sense!)

- After a moment, the tool will stop in the axle

- By forcing a little, the axle will unscrew

This solution is certainly the most effective and least dangerous. Try it first!

No ratchet tap wrench? a wood screw could help you!

If you do not have any ratchet tap wrench, that the hex imprint is in good condition but the axle remains stuck despite of your efforts. Another solution may be to:

- Find a thin drill about 2 to 3 mm

- Block the frame, the threaded side of the axle on top

- Take a punch and a hammer to make a hollow in the head of the axles (threaded side). This small area will be useful to guide the drill. The hollow must be in the center of the axle.

- Go down the drill in the axis of the axle

- Dig the material slowly over about 1 cm

- Insert a wood screw into the hole you just created and screw

- After a moment, the screw will stop … and then it works like a ratchet tap wrench. By screwing the screw, you remove the axle!

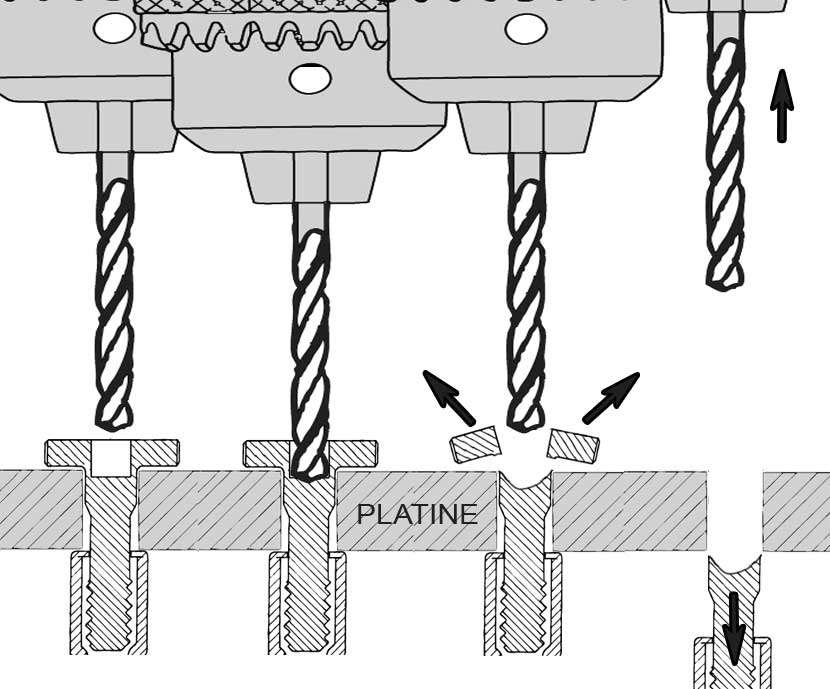

Drilling a single axe

Unlike an axle with a screw, you have to drill the axle on the threaded side! And there is a work of patience and attention to detail. Another thing, whatever happens, the axle will not survive the operation!

The principle: an axle that resists can be weakened by creating and widening a hole on the threaded side of the axle. The purpose is to dig a hole about 2 mm wide to soften the material and facilitate the extraction of the axle without damaging the thread of the frame.

Be careful! Using a big or imprecise drill might damage the thread of your frame!

- Find a thin drill about 2 to 3 mm

- Block the frame, the threaded side of the axle on top

- Take a punch and a hammer to make a hollow in the head of the axles (threaded side). This small area will be useful to guide the drill. The hollow must be in the center of the axle.

- Go down the drill in the axis of the axle

- Dig the material slowly over about 1 cm

- The threaded part of the axle will weaken and loose rigidity

- try to unscrew again

- If it still does not work, widen the hole a little

- Normally, the axle be removed easily. Now you just have to buy a new one… but at least your frame is saved!

Useful links

How to clean and take care of your bearings?

How to extract bearings from wheels?

Inverting and looking after your inline skate wheels

Maintenance of inline skate boots

The maintenance of your skate frame

Pictures: Alfathor, Xi, Yannick

Thanks to David Lim, Xi…

Patrick

28 mars 2014 at 0 h 22 min