How are made skate wheels?

Did you know that the appearance of plastic wheels revived the skating trend in the 80's? Before they were inflatable, or made of wood or metal and did not have the comfort and rolling performances of today's equipment. Today, the manufacturers fight over the market and never stop improving their products. We have cut one open for you...

Par alfathor

A type of wheel per type of practice

To each practice suits a type of wheel with special hardness, diameter and qualities:

To each practice suits a type of wheel with special hardness, diameter and qualities:

- Fitness and speed skating go for quite soft models (78 to 85A) and big diameters (80 to 110mm) with elliptic profiles;

- Aggressive skating uses small wheels (54 to 62mm), hard (89 to 100A) and flat;

- Hockey favors rounded profiles, etc.

In most cases, they are made of polyurethane.

All-terrain skates sometimes use models equipped with pneumatics (the Coyote by Rollerblade).

Some low end skates distributed in supermarkets have hard plastic wheels and others, destined to rain, may be made of rubber to improve their grip.

The manufacturing processes

The wheels are manufactured according to two processes: injection or molding. For the injection process, the technological skills are the same as those needed for boots.

Four manufacturing stages:

- designing

- selection of the materials

- making of the molds

- machining

Designing

The wheels are designed by computer (CAD computer aided-design) in a committee: two years of work are needed to design a wheel, from the start of the designing to mass production.

The wheels are designed by computer (CAD computer aided-design) in a committee: two years of work are needed to design a wheel, from the start of the designing to mass production.

The designing of a wheel is divided into two parts.

First, the central part of the wheel: the core, which is equivalent to a rim. The software used by the Shaark Company is called C.A.T.I.A. and was developped by Dassault Developpement to design the bodies of fighter planes in three dimensions.

The second part of the designing will be about the on-core, wich is equivalent to a tire.

Selecting the materials

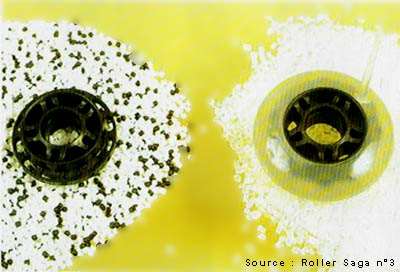

The core is made of Nylon or Rilsan, which are granules in their first state (see picture). Those granules are then often mixed with carbon or other materials to reinforce the structure of the core. The compositions change according to the manufacturers and their secrets are jealously kept.

The on-core is generally made of polyurethane as mentioned above. Today, some models appear with aluminum or carbon cores, more rigid but also more expansive.

Testing the prototypes

Tests are made on prototype wheels to evaluate the materials: rebound, resistance to wear, grip, hardness of the polyurethane, resistance of the core and above all of the on-core. The plastics are chosen according to their results to the different tests.

Once the most suited raw materials are chosen, the molds that will serve to produce the final models are designed.

The making of the molds

Here again, the molds are designed by CAD, just like the wheels, based on specific computer models for each model of wheel. A first metal mold made of steel is cut by laser for the core. A second mold is made for the on-core.

The designing and the finishing of a mold may last almost six months. Let’s notice, on the left of the mold (see picture), the injection canal through which will be propelled the raw material to be injected. Thousands of wheels will have to be produced in order to pay off the investment of several dozens of thousands of euros.

The machining

A mix of melted materials is injected in the first mold for the core, then heated. The second mold is then used for the on-core in which the molten polyurethane is injected.

A mix of melted materials is injected in the first mold for the core, then heated. The second mold is then used for the on-core in which the molten polyurethane is injected.

It will fit closely the shape of the core to take the final shape of the wheel that we all know. Let it cool down, turn out, it’s ready!

Recent technological innovations

There are now wheels of all kinds: bi-density (K2), ‘air’ (Hyper), with aluminum core (PSI), or rain-wheels (Continental).

The last years have witnessed the increase of the diameter of speed skating wheels, but also the appearance of hollow or lenticular cores, and of bi-density on-cores.

The appearance of 100mm and then 110mm wheels on races aroused new questions on their quality, their design and their wear. The story of the race to performance does not seem ready to end soon (see first link below)…

Links

The manufacturing processes of skate frames

How are made rink-hockey skates?

RollX factory: skating Wheels manufacturing

The manufacturing of a pair of roller skates

Speed Skating: The age of made-to-measure boots?

Translation: Chloé Seyres

Photos: Roller Saga and all rights reserved