Please, build me a modular skate park!

Par alfathor |

Publié le 31 May 2006 |

Mis à jour le 3 November 2020 |

Catégories :

All

Aggressive skating

All

Aggressive skating

| Sous-catégories :

manufacturing of roller skates

manufacturing of roller skates

| 27423

| Tags :

skatepark

skate park

skate park production

skate park production process

stages to get a skate park

modular skate park

Around the world, cities are installing skate parks. In the past few years, even if the number of concrete skate parks seriously increased, modular equipments are still majority. We met with the 3R Skateparks company to learn more about their production process…

From idea to installation… interview with Christian Richez (3R Skateparks)

The installation of a skate park is not just a simple purchase as one might buy bread at the bakery. However, many cities still make the strategir error to be equipped without consulting the main users: rollerbladers, skateboarders, BMX and scooters. A long upstream work is needed to provide an equipment that will best meet all individual and specific needs.

The installation of a skate park is not just a simple purchase as one might buy bread at the bakery. However, many cities still make the strategir error to be equipped without consulting the main users: rollerbladers, skateboarders, BMX and scooters. A long upstream work is needed to provide an equipment that will best meet all individual and specific needs.

Once the type of equipment is determined, it is time for free play of competition among manufacturers. But how these modules are manufactured? Christian Richer details the main stages from the design to the installation of a skate park.

Hello Christian, how is the meeting with local councillors and future users of skate parks?

Christian Richez : In general, the sports councils or some users contact us, either directly or through an agent. It is also possibale that we would meet them in order to define what are their demands and needs.

1) Either the sport council calls directly…

In France, the law requires mayors to seek at least three different quotes to compare (this applies up to 90,000 Euros (excluding tax))

2) … or starts an invitation to tender

This is the most common case. This process is more binding because it is not a simple estimate that the company returns to the city but an entire file.

In addition, a consultation is often signed by the mayor or the person who has followed the case when the tender is signed by the mayor… but only after the choice of the contracting office. The problem is that the contracting office does often compare the prices and that’s all. It does not take into account the quality, finish and comfort for users.

A consultation is quicker and simpler for everyone. In general, the product meet the needs of the young users better.

A tender generates red tape that, in addition, lead to the purchase of a price without taking into account all the work of those who led the project..

|

|

What are the steps in the conception and installation of a skate park?

Christian Richez : We can distinguish a dozen stages before starting the installation of the skate park. We will detail them one by one…

Christian Richez : We can distinguish a dozen stages before starting the installation of the skate park. We will detail them one by one…

1) We draw the plans of modules, then edit listings with the cutting

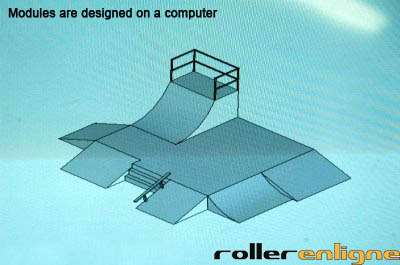

This plan details the parts that must be cut. It also specifies the sizes of the cut. Most modules are primarily designed using a dedicated software. Sometimes customers ask us for specific shapes. We study the feasibility and therefore we offer solutions. It always starts with the tubes.

2) Cutting the tubes

Then comes the cutting of the tubes, which is done with an aluminum saw. They will be used to build the structure of the various modules.

3) Filling the tubes

Then we fill the tubes with sand to insulate. This process allows us to considerably reduce the noise when using the modules. They are also filled with glass wool. The result is a noise almost zero!!

4) The creation of the framework

The next step is to create the structure of the module itself.

Then come the weld of the elements. We design the shape of the module: banks, curves, quarter-pipes, half-pipes …

5) The phonic joints

Each element of the module is separated by phonic joints. The joint is added before placing the plates on the frame. Again, we reduce the noise considerably.

6) Installation of the rolling surface

Then we screw the the rolling surface on the frame.. The plates were first cut on a huge machine. Previously, we cut the platines by hand, it took hours!

Now, in ten minutes, we can cut out several plates of aluminum! After cutting, the plates are sent to another machine that give them the desired radius of curvature..

7) Finish of the surface

During production, we add support pieces to solidify the structure. We take them away at the end of the process.

Then we planed the angles to obtain leading edge up to 3 mm in order to fit the ground at best. We finish the job by sanding the welds …

8) Sanding

Then the module is sent out of the building. We do the sanding outside. This process gives the modules a so characteristic granularity. We outsource this stage.

A portable compressor is used to send sand under pressure on the surface. We must then re-relax a bit the leading edges because the sand compressor creates a thermal shock that distorts the rolling surface..

9) logo

The last step is to apply our logo ‘3R Skateparks” on the module. It is now ready to go!

10) Transport

The different modules that compose the skate park are loaded into a trailer. They are shipped to the place of installation, complete or in spare parts if too large.

11) The installation of modules

The modules are then reassembled on site. It is necessary to secure the ground: we use a lag screw for safety reasons. We inject a chemical sealant and the module is fixed to the ground..

12) Administrative

Then we send to the client a certificate of compliance. Sport equipment is standard. The cities are covered. It is an obligation of manufacturers to municipalities. We must also often provide a ground plane with the position of the modules on the area, indicating their dimension, their spacing…

13) Now it’s time to ride!

|

|

Useful links

Photos: Alfathor

Thanks to 3R Skateparks

and Christian Richez

Auteur

Alexandre Chartier

''alfathor''

Alexandre est le fondateur et webmaster de rollerenligne.com depuis 2003. C'est un passionné de roller en général, tant en patin traditionnel qu'en roller en ligne. Il aime le patinage à roulettes sous tous ses aspects : histoire, économie, sociologie, évolution technologique... Aspirine et/ou café recommandés si vous abordez un de ces sujets !

3rskateparks.com

3rskateparks.com