Dual density skate wheels: Where does the technology comes from and what is the use of it?

There are more and more dual density wheels on the market, for speed skating, long distance, freeskate, roller derby, hockey and even aggressive skating. What is the use of this technology? Answers...

Par alfathor

A minor innovation but still an innovation…

Fual density: What is it?

The concept of dual density is quite simple in fact: The wheel is made of two polyurethanes with two different densities. Most of the time, the inside part of the on-core is softer and the outside layer is harder.

The concept of dual density is quite simple in fact: The wheel is made of two polyurethanes with two different densities. Most of the time, the inside part of the on-core is softer and the outside layer is harder.

Inside urethane, softer for more comfort

Outside urethane, harder for more durability

What is the use of it?

A wheel with soft polyurethane theoretically offers a better grip because it squeezes more. It has more surface in contact with the ground. It also provides a better rolling comfort with less vibrations. But it wears out faster.

On the other hand, a skate wheel with hard polyurethane logically offers more rolling because it doesn’t squeeze that much against the ground. The surface in contact with the ground -and thus friction- is reduced. Consequently, it is less grippy. And it wears out more slowly.

For a discipline like speed skating on track, you obviously seek for optimal rolling, but also maximum grip in bends to keep your trajectory and speed. In order to have both, you have to rely on the flexibility of the polyurethane and that of the hub.

The purpose of a dual density wheel is thus to best combine the features of hard and soft urethanes. Manufacturers place the soft part at the heart of the wheel so that it doesn’t wear out too fast, and provides more comfort and rebound. The harder urethane part is placed on the outside to keep the optimal rolling features.

It goes without saying that the bigger the diameter, the bigger the effect of dual density. One may question the use of dual density technology on small diameters (under 80 mm).

K2: Pioneer of dual density

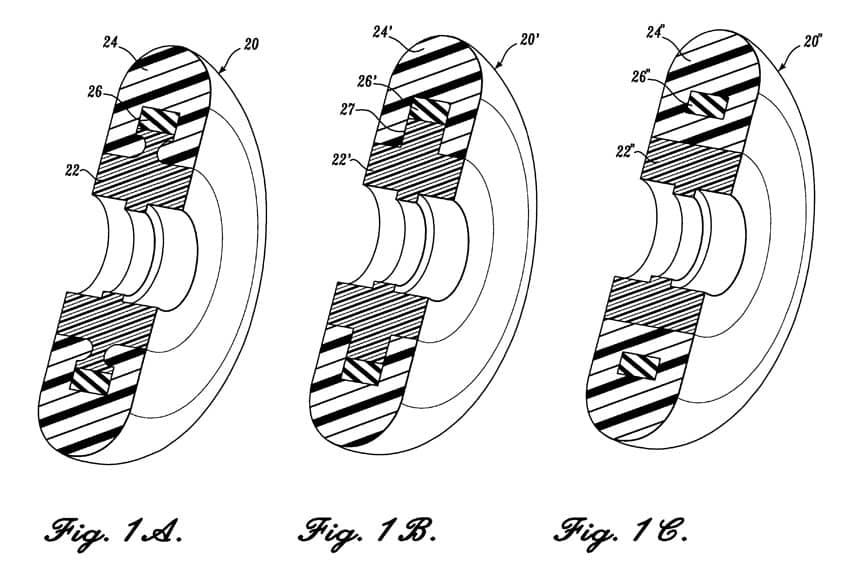

Several brands would have explored the field of dual density at the end of the 90’s but K2 claims the paternity of the invention. The firm filed a patent in 1997, containing the blueprints of dual density (see figure) with three different configurations, on wheel hubs, with and without interlock. The inventors are John A. Roderick, Albert C. Chiang and James A. Vandergrift.

Several brands would have explored the field of dual density at the end of the 90’s but K2 claims the paternity of the invention. The firm filed a patent in 1997, containing the blueprints of dual density (see figure) with three different configurations, on wheel hubs, with and without interlock. The inventors are John A. Roderick, Albert C. Chiang and James A. Vandergrift.

At the time, wheel hardnesses were different but the principle was the same: The inside part was very soft (70A) in order to absorb vibrations and cushion shocks. The outside part was a little harder (78A) for more reactivity.

K2 equipped its high-range long distance skate models with that dual density technology.

The comeback of dual density

The idea was going to remain in stand-by for several years before various disciplines took hold of it again in the last decade.

MPC started to develop its dual density wheels in 2002, at the instigation of John Roderick, the president of the firm. Rings a bell? He was formally at K2! The later hired his former K2 colleague, Dr. Albert Chiang.

The first tests in competition took place in 2004, during the world championships in Italy, where Luca Presti won the 300 m with MPC Black Track 84 mm wheels.

In 2007, MPC launched the VT (Variable Traction), a dual density speed skating wheel with a hardness of 88A, against mostly 85A wheels back then. MPC, through the intermediary of Mearthane, would also have filed a patent on the invention. With those wheels, Diego Rosero, aged 26 at the time, would have taken a 3-min lead on Joey Mantia and Massimiliano Presti during a preliminary marathon at the Worlds of speed skating in Cartagena, Colombia.

In 2008, Bont launched its promotional campaign on the G4, a dual density wheel made in USA and designed for speed skating.

In 2013, dual density also developed in aggressive skating with the UnderCover Dual Density 58 mm models. Here again, those wheels are made in USA. It is quite surprising for aggressive skating, given that the effect of dual density is limited by the small diameter of the wheels.

Again in 2013, Powerslide commercialized the dual density Juice AMP wheels, designed for roller derby. Purpose: improving the grip of the wheel in bends, in increasing the surface of polyurethane in contact with the ground.

Today, it is hard to imagine a high-range wheel that wouldn’t be designed with that technology in speed skating: Atom, Matter, MPC, RollX… all those brands had to create their own models.

dual density is everywhere in skating

The use of dual density is not limited to skate wheels, it has also been used for years already for skate boots. The technology is also used for slalom cones, by Seba. dual density is everywhere!

Links

Roues : innovations technologiques récentes

Undercover : des roues de street à dual densité

Test des roues freeride Defcon 80 mm

Test de la roue de roller derby AMP Juice

Test : Roues MPC VT (Variable Traction) 100 mm

Translation: Chloe Seyres

Photos: K2 and Powerslide

Martyn

21 septembre 2015 at 17 h 31 minGeoffrey Boyer

28 janvier 2015 at 15 h 16 min