Anatomy of an inline skate wheel

Wheels are the centerpieces of a skate and its only contact with the ground. They condition skating according to numerous parameters: their shape, their diameter, their hardness, the flexibility of their core, etc. To each specialty corresponds a specific need with a specific wheel model...

Par alfathor

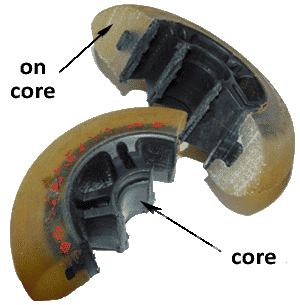

Description of a wheel

Just like cars with different types of tires according to their use (rain, snow, circuit…), skates have wheels with variable characteristics according to the considered specialty. In speed skating, you want to gain and maintain maximum speed: Then you choose big diameters. In Hockey, you need grip and reactivity: You’d rather take small diameters, soft and strong. In order to fulfill all these opposite conditions, manufacturers play on the core and the on-core.

Just like cars with different types of tires according to their use (rain, snow, circuit…), skates have wheels with variable characteristics according to the considered specialty. In speed skating, you want to gain and maintain maximum speed: Then you choose big diameters. In Hockey, you need grip and reactivity: You’d rather take small diameters, soft and strong. In order to fulfill all these opposite conditions, manufacturers play on the core and the on-core.

Nature and properties of polyurethane skate wheels

On most of the current skate models, wheels are composed of a polyurethane on-core (or polyethylene).

There are a couple of other models with a rubber on-core, especially in ski-skating and all-terrain skating.

Wheels make contact with the ground. They bring grip and speed to the skates.

In order to modify the reactions of a wheel, you can play on different factors:

- Its total diameter in millimeters (generally from 42 to 110mm)

- The hardness of its polyurethane on-core, stated in Shores (from 74 to 100A)

- The profile of the polyurethane on-core (round, square, elliptic)

- Its core (full, open…)

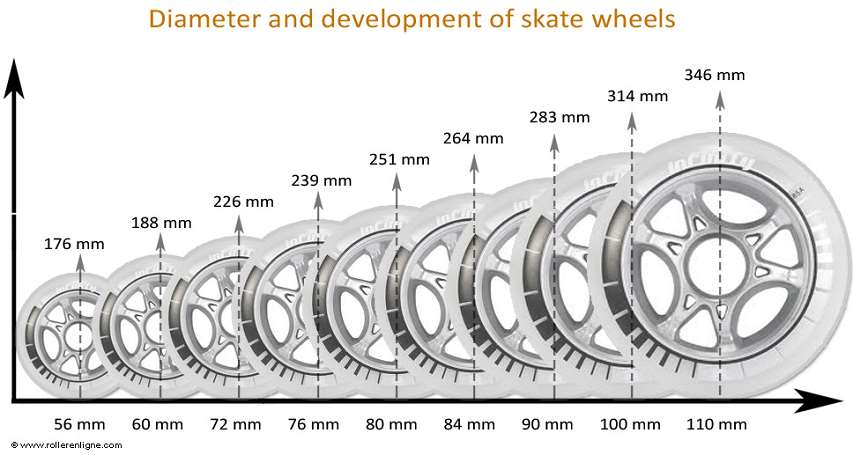

The importance of the diameter

The diameter of a wheel is stated in millimeters. Our data base and our bibliographical researches enabled us to determine that diameters are spaced out between 42 and 110mm for standard skates (except all-terrain skates). The biggest diameters are used in speed skating and the smallest ones in aggressive skating.

The bigger the wheel, the faster the skate once it takes full speed: the development (distance covered by turn of wheel) and the stored kinetic energy are bigger.

On the other hand, a skate with big wheels will lose reactivity at the start. It will also be less easy to handle as the radius of the turns is bigger and last but not least, the center of gravity will be higher.

The smaller the wheels the more reactive and easy to handle the skate, and the faster you reach the maximum speed, although it is harder to maintain it is by lack of inertia.

Shores: hardness measure for polyurethane wheels.

The Shore, stated with an “A”, is an American unit commonly used to measure the hardness of wheels. It’s not peculiar to skating. This measure is spaced out around between 74A and 100A in skating. It is checked thanks to a durometer, a measurement machine calibrated with weights and measures.

In order to be valid, these measurements must be done on a flat surface of a square meter, which is just impossible with a manual durometer on a wheel. Don’t be surprised if you find a different result of one or two shores if you do the test yourself one day…

The higher the shores:

- The harder the wheel

- The less comfortable the wheel

- The slower it will wear out

- The less grippy the wheel

On the other hand, the softer the wheel:

- The faster it will wear out

- The grippier as it will take on the shape of the ground

- The less vibrations

Soft wheels will be particularly suitable for street-skating, for which you favor comfort. They can be used in hockey too for a better grip.

Hard wheels wear out more slowly but offer less grip. They are generally used in aggressive skating (ramps, …) or in speed skating because they offer a better rolling.

Polyurethane on-cores

Their diameters, hardnesses and profiles vary. A wheel is made of a core on which is inserted an on-core that is the rolling surface. Wheels are identified thanks to their brands, their numbers, their chemical natures, their hardnesses and last but not least their diameters.

Polyurethane (P.U.) is a composite made of plastic (thermoplastic polymer) used in the manufacture of inline skates. It was first used in 1979 in the manufacturing of skateboard and skate wheels.

Since then, it has become standard on every model, with a few exceptions (pneumatic on some all-terrain and down market models).

From wood to plastic revolution

Before, wheels could be made of wood (boxwood for speed skating) or metal. They would wear out very fast or make too many vibrations.

The use of P.U. is a small revolution as it gathers the advantages of softness, comfort and abrasion resistance… so that wheels hold the distance, wear out less fast and considerably improve the comfort of the skater…

There are also PVC wheels which are used on very down market products distributed in hyperstores. This material is hard and the rolling comfort is rudimentary.

The diversification of a market

The use of polyurethane enabled a real segmentation of the skate wheel market. It was so easy to use that it favored the creation of wheel types fitting the needs of skaters for all disciplines. You can find:

- Small and hard wheels for ramp/skatepark/aggressive skating

- Bigger and soft wheels for street skating

- Harder wheels with very big diameters for speed skating

- Even notched or pneumatic wheels for all-terrain skating

- Etc.

Two aesthetic improvements impressed the evolution of polyurethane wheels: transparent and translucent wheels. The color of translucent wheels is conveyed by the core.

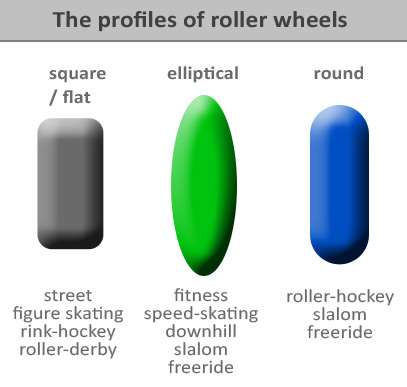

The on-core profiles

The profile of the wheel can be of three different shapes:

- Thin: for less resistance. A soft wheel (78A to 82A) suits for fitness skating but wears out faster. This type of profile is also used in speed skating but with harder wheels (83A to 87A). The skates are then easier to handle but also less stable (less grip).

- Round: more reactive and easier to handle, destined to hockey skating for example. This type of wheel can be very soft (74A to 80A). This shape brings a good stability but engenders more friction. You can also find harder wheels but they are less grippy.

- Almost flat or “square”: for aggressive skating (for a better stability and a higher life expectancy). These wheels are very hard (88A to 100A). As their name indicates, they provide rolling.

On the skate models currently on the market, there are between 2 and 5 wheels. Some models in the past could have between 1 and 8 wheels.

The wheel cores

To keep it simple, you can distinguish between soft and hard cores, according to the materiel they are made of. The most commonly used are nylon and Rilsan. The latter is generally mixed with carbon fiber to improve its strength. Glass fiber and carbon establish themselves more and more in speed skating.

The materials of which the core can be made:

- Plastic

- Rislan

- Carbon composite

- Glass fiber composite

- Aluminum

If you’re looking for comfort, you’d rather restrict yourself to “plastic” materials, softer and more elastic. The latters filter vibrations better than aluminum cores which are harder and destined to performance. They disappeared in skating because they were too hard and not flexible enough. You can find them now on scooters.

The structure of cores

According to the wheel models, the core can be more or less full, or even non-existent.

According to the wheel models, the core can be more or less full, or even non-existent.

Which is particularly the case in aggressive skating. Star-shaped cores with points, made of nylon or composite materials are used in the other disciplines.

Open cores

They offer lightness and suit to street skating (fitness) and to speed skating. Star-shaped cores offer more lightness and comfort to the wheel and absorb vibrations.

Wheels must be as light as possible. The weight of a “turning” part is very important as for performance: it is better to gain 50g on the wheels than 200 or 300g on the rest of the skate.

Semi-open cores

They are light but they also more robust which is perfect for hockey or free-skating.

Full cores

Most of the time, they are dedicated to aggressive skating, and they are stronger. Wheels with full cores have a higher life expectancy, and you can find them on small diameter wheels. Sometimes when wheels are very small, it happens that bearings must be directly inserted in the on-core.

Removable cores

Wheels with removable cores have been recently introduced. Exile has just proposed a wheel with a removable aluminum core and a changeable on-core (polyurethane part).

Just as we’ve seen, manufacturers are looking for the best adequacy to practice. They have to take into consideration extremely varied criteria, including hardness and softness, and resistance and comfort. So that brands like K2 try to gather these properties in using double density polyurethane wheels.

Some types of wheels

Luminous wheels

Some manufacturers propose luminous wheels working without battery. They have LEDs that are supplied thanks to a dynamo system. They can be seen by in the day light and are luminous at night. The LEDs are tilted to the side for a better visibility.

Some manufacturers propose luminous wheels working without battery. They have LEDs that are supplied thanks to a dynamo system. They can be seen by in the day light and are luminous at night. The LEDs are tilted to the side for a better visibility.

Anti-rockers

These are full wheels, of very small diameter placed on both sides of the H block in aggressive skating. You’re not bothered when you try to slide on a big bar thanks to their small size. They are not necessarily equipped with bearings.

All-terrain wheels

They are the opposite of anti-rockers. Their diameter can be more than 150mm. They are specifically designed for all-terrain skating, and the technology of these products is very often quite close to that of car wheels: tubeless… watch out for flat tires!

Air tube wheels

These are the latest models in technology, they are comfortable and easy to handle. Nike proposed these products some time ago, but it didn’t turn out to be a big success.

Phosphorescent wheels

In order to be visible, these wheels get loaded with daylight to become phosphorescent at night. Warning: they do not replace the retro-reflective bands on safety jackets.

Useful Links

Maintenance of a wheel

Skating wheels manufacturing

Anatomy of a pair of aggressive skates

Anatomy of a pair of ski-skates

Anatomy of a pair of inline skates

Anatomy of an inline skate boot

Anatomy of an inline skate brake

Anatomy of skate axles and spacers

Anatomy of an inline skate frame

Anatomy of an inline skate liner

Translated by Close Yr E’s

Photos: all rights reserved