How to clean and take care of your bearings?

As an essential part of your skates’ performance, your bearings have to be closely looked after. You don’t always necessarily have to dismantle them. But if this is the only option left, here are a couple of tips to do your best.

Par alfathor

Try to avoid dismantling your bearings so far as possible.

Firstly: You don’t necessarily have to dismantle your bearings at each cleaning.

Firstly: You don’t necessarily have to dismantle your bearings at each cleaning.

As far as possible, avoid doing so as it is a painful operation for the equipment: loss in waterproof enclosure, distortion of the caps and balls – most of the time, the gain isn’t worth the potential risks.

The less mistreated the more waterproof. Do not dismantle or only if necessary (water, sand, screeching…)

A light and efficient maintenance

Just like for cars or machines the maintenance of which must be regular.

Check your equipment every 5 to 10 outings, or according to the intensity of your practice and to the weather.

Start with:

- Taking the wheels off of the frame,

- Cleaning the surface of the bearings, without taking them off of the wheels, with a toothbrush, kitchen paper or an air gun,

- Making circles on the surface to take off the film of dust,

- Using the occasion to give the frame a quick wipe and brush.

During a race…

If you don’t have the time and/or the tools for the maintenance, use 3-in-1 oil!

- Spray on each bearing, spinning the wheels slowly in order to spread the oil uniformly,

- Then spin the wheels faster to take off the surplus,

- Clean up the wheels with kitchen paper or a rag to avoid slipping and falling on a remaining drop of oil.

Taking off the bearing to check its nature

Step 1: taking the bearing off of the wheel

Your bearings are stuck because your skates remained in a corner a few hours or a few days too many. All you’ve got left is to get your tools and take a couple of hours to dismantle them.

Your bearings are stuck because your skates remained in a corner a few hours or a few days too many. All you’ve got left is to get your tools and take a couple of hours to dismantle them.

At first you have to take the bearings off of the wheels. If you don’t know how to proceed, check out: How to take your bearings off of your wheels

Tools needed for the maintenance of bearings

- Grease removing agent

- Oil, grease or gel to lubricate

- Needle or pin to extract the circlips

- Waterproof container (i.e. original box, aspirin tube)

- Rag or kitchen paper

Step 2: cleaning the surface

Once the bearing is extracted from the wheel, you have to get rid of the dust at the surface in order to determine more easily which type is your bearing.

- If you have already cleaned the surface before taking the bearing off of the wheel, you can finish up with kitchen paper.

- Use a toothbrush to expel the dust,

- Make circles from the inside to the outside of the bearing, in order to avoid the dirt to enter the cage under the cap,

- End up with getting rid of the surplus of grease with kitchen paper.

Tip: For cleaning the bore (central hole), fold the corner of a kitchen paper to slip on the bearing, this will take off the dirt quickly.

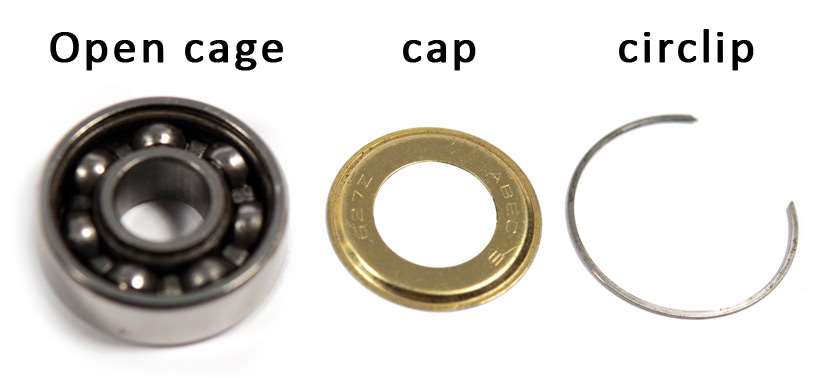

Step 3: check the type of bearing

Then you have to make sure that your bearings may be dismantled. Back in the days you could find a lot of indications on the surface of caps (types of bearings, etc.), but because of marketing, caps have become advertising spaces where all the useful info have disappeared most of the time!

Warning! Some bearings may not be dismantled! Check first:

- Elastomer (plastic) caps for 608DD bearings

- Metal caps for 608ZZ (there are also circlips on those ones)

- Set bearings may only be lubricated with 3-in-1 oil, not dismantled.

Dismantling of a 608ZZ bearing with metal caps

Step 2: taking off the caps

For metal caps, you have to take off the circlips (metal rings in the shape of a C) in lifting one end with a needle. This is a long and meticulous operation but it is needed if the bearings are really dirty.

A quick overlook will enable you to judge of the state of the balls. If they are starting to rust then your bearing is approaching the end.

Step 3: Grease removing

- Immerse the bearings in a waterproof container full of grease removing agent or “white spirit” (the latter may be corrosive for your bearings)

- Shake energetically to separate the dirt from the bearings (protect your eyes in case of splashing)

- Allow the agent to act 5 minutes

- Take off the bearings of the liquid

- Display them on a kitchen paper, it will absorb the liquid

|

|

|

|

Step 4: drying

Drying the bearings before greasing them is important.

- Spin the bearings on their axes, the agent will go off with the centrifugal force

- Finish in wiping with kitchen paper.

Tip: You can use an air gun, but don’t spin your bearings too fast or too long without lubricant. If you use this technique, protect your eyes from splashes.

Step 5: lubrication

Depending on your use, the season and your financial means. If you’re a speed skater, forget about grease and opt for bearing oil or gel.

Depending on your use, the season and your financial means. If you’re a speed skater, forget about grease and opt for bearing oil or gel.

If you’re a street skater and you don’t really want to bother about maintenance, choose grease, particularly in winter time as it improves waterproof enclosure. It will protect your bearings from bad weather and secure a good life expectancy.

You can use oil but being more liquid that grease, it doesn’t protect the bearings as well and you’ll have to check more often.

Tip: Whatever the lubricant, a few drops are enough. Don’t drown your bearings; they will disgorge the surplus on the wheels, making them slip! Moreover, grease catches dust.

Step 6: reassembling and taking off of the surplus of lubricant

- Put back the caps

- Put back the circlips

- Spin your bearings in-between your fingers as fast as possible to eject the surplus of lubricant

- Clean the surface of the bearing

- That’s it!

Bearings with elastomer caps

The task is easy and similar to the previous case:

- Insert the pin between the cap and the central axis of the bearing

- Pry carefully: the caps are flexible and fragile

- Lift, the cap goes off, there is no circlip

A couple of tips to clean…

Everybody have their own special recipes as for bearing maintenance…

Everybody have their own special recipes as for bearing maintenance…

For grease removal: the gherkin jar technique

This is an easy solution to avoid dirtying your fingers in fishing out the bearings in the bottom of the container: keep your gherkin jars with the basket!

Thanks to Slide59

Scalding your bearings in hot water

The swirls will take off all the dirt from the balls and the axes… the grease removes by itself with this technique – no grease removing agent needed.

Compressed air

The most efficient and fast remains the pressurized water gun and the air gun (it’s also the most playful – who doesn’t want to hold a gun?)

It’s extremely fast and clean. Put your bearings in-between two metal shelves/grilles/drains or on a long screw or whatever, in order that the bearings don’t go away.

If you hold your bearings in your hand, wear gloves to avoid metal splinters. Wear security glasses too to protect your eyes from any spitting.

Bont bearing cleaner

Recently, we have tested the bearing cleaner by Bont – and we must say that it does work pretty well.

Concept: the bearing is put on an axis spinning very fast in some liquid. The centrifugal force evacuates the dirt.

Lubricating

Whatever the lubricant, you can put it in a syringe for more precision.

- Leave a drop of grease between each ball, but not too much

- Reassemble the circlip

- Spin the bearing on its axis to take off the surplus of grease and finish with a rag.

Thanks to Franklin for his tips

A good tip to take the rust off of your bearings

Dunk your rusted or seized up bearings into L.H.M. (Citroën brake fluid) for one night.

On the next day, spin them a bit to take off the rust, then clean them with a grease removing agent and re-grease them. They will be like new!

Thanks to Jean-Seb

Maintenance of your spacers

If they are made of plastic, just check from time to time that they didn’t explode. If they are made of metal, just take off the dust.

Warning: if you want to change your spacers, there are different references and two diameters: 7 and 8 millimeters.

Useful Links

Inverting and looking after your inline skate wheels

How to clean and take care of your bearings?

How to extract bearings from wheels?

Maintenance of inline skate boots

The maintenance of your skate frame

Test: ILQ-X MR2 Twincam bearings

Video demo of how the DS Innov key works

Bont Bearing Cleaner by Moana (French)

Translated by Chloé Seyres

Pictures: Alfathor